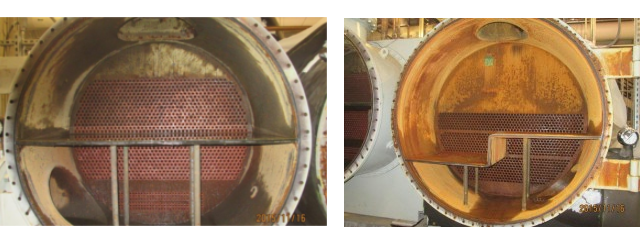

Cooling Towers Cleaning Maintenance for Winter

An ideal environment is provided by cooling towers for the growth and incubation of many organisms, including the Legionella bacteria. This problem is exacerbated by periods of non-use (winter lay-up). A consistent biocide program can reduce the risks, but it is ideal to clean a cooling tower at least twice a year. All cooling towers…

An ideal environment is provided by cooling towers for the growth and incubation of many organisms, including the Legionella bacteria. This problem is exacerbated by periods of non-use (winter lay-up). A consistent biocide program can reduce the risks, but it is ideal to clean a cooling tower at least twice…

View moreCooling towers are used to cool down water that goes through chillers and other heat exchanger equipment. Ultimately, it is a heat rejection device which utilizes the evaporative cooling process to transfer waste heat from the atmosphere. Not having your cooling tower properly maintained can lead to leaks and standing…

View moreUsing epoxy coatings and epoxy-coated structural liners offers many benefits, including saving both time and money over traditional pipe repairs. Damaged or deteriorating pipe systems can be expensive to replace, especially those that are located in hard-to-reach locations or inaccessible without selective demolition. Fortunately, common pipe systems can be rehabilitated…

View moreUsing epoxy coatings and epoxy-coated structural liners offers many benefits, including saving both time and money over traditional pipe repairs. Damaged or deteriorating pipe systems can be expensive to replace, especially those that are located in hard-to-reach locations or inaccessible without selective demolition. Fortunately, common pipe systems can be rehabilitated…

View moreCooling towers are used to cool down water that goes through chillers and other heat exchanger equipment. Ultimately, it is a heat rejection device which utilizes the evaporative cooling process to transfer waste heat from the atmosphere. Not having your cooling tower properly maintained can lead to leaks and standing water which…

View moreWith cool weather upon us, now is the time to have maintenance on your building's chilled water system. If your chiller, condensate pans or cooling tower could use a coating system to protect and preserve your equipment, contact us today! We probably already work for your chill water maintenance provider, Carrier,…

View moreWhen you are planning an epoxy coating project, it is important to choose the right epoxy coating that best suits your needs. Epoxy coatings are available in a variety of thickness and styles that can be customized to meet your requirements for durability, functionality and aesthetics. PES Solutions can help…

View moreCoatings for secondary containment are highly recommended to control chemical corrosion. Protective systems to safeguard our environment from hazardous materials and chemical waste are demanded by government agencies, concerned corporations and individuals. Whatever your condition, PES Solutions has a chemical resistant system for all your containment needs. Secondary Containment Liners…

View moreCoatings for secondary containment are highly recommended to control chemical corrosion. Protective systems to safeguard our environment from hazardous materials and chemical waste are demanded by government agencies, concerned corporations and individuals. Whatever your condition, PES Solutions has a chemical resistant system for all your containment needs. Corrosive Environments The…

View morePES 205 Ceramic HT Fluid PES 205 Ceramic HT Fluid is a two component solvent free epoxy novolac coating designed for high temperature immersion conditions. The product, once cured, can withstand continuous immersion conditions up to 266ºF (130°C) and can upgrade the performance of conventional materials of construction. The material…

View more