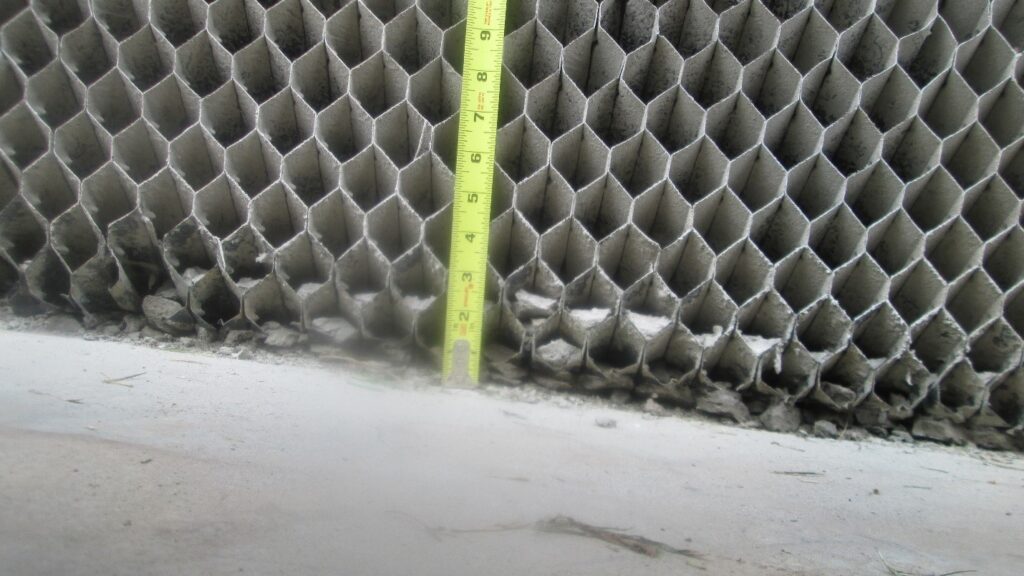

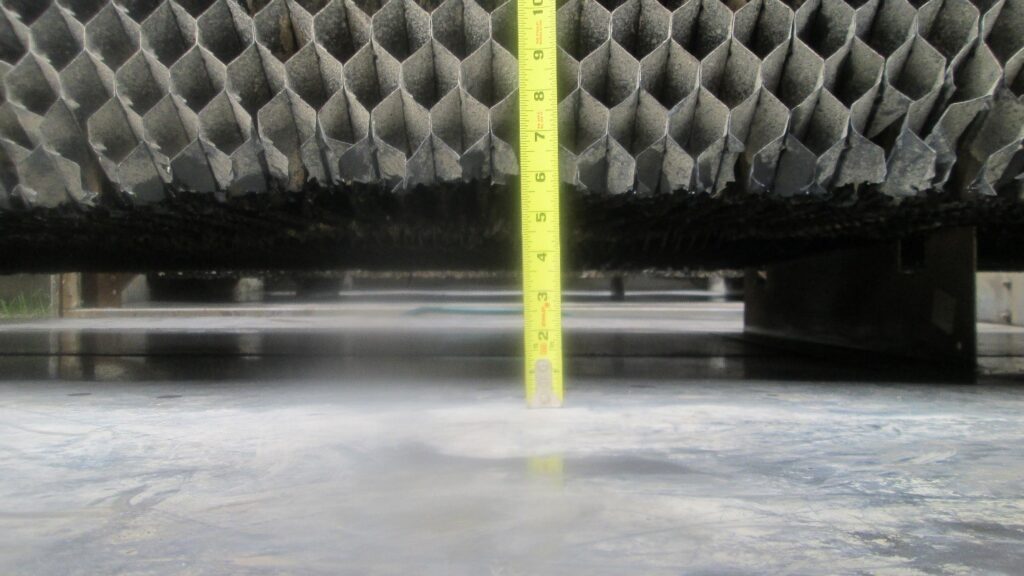

One especially important piece of equipment in your HVAC and process water cooling systems is your cooling towers. PES offers many easy solutions to the long-term performance of these towers, such as our Lone Star Fill Cut, where we cut and remove the bottom 5.5″–6″ ” of the fill media. This process allows easier access to cleaning the remaining fill media as well as sealing the seams and providing a PES chemical resistant coating to the cooling tower basin.

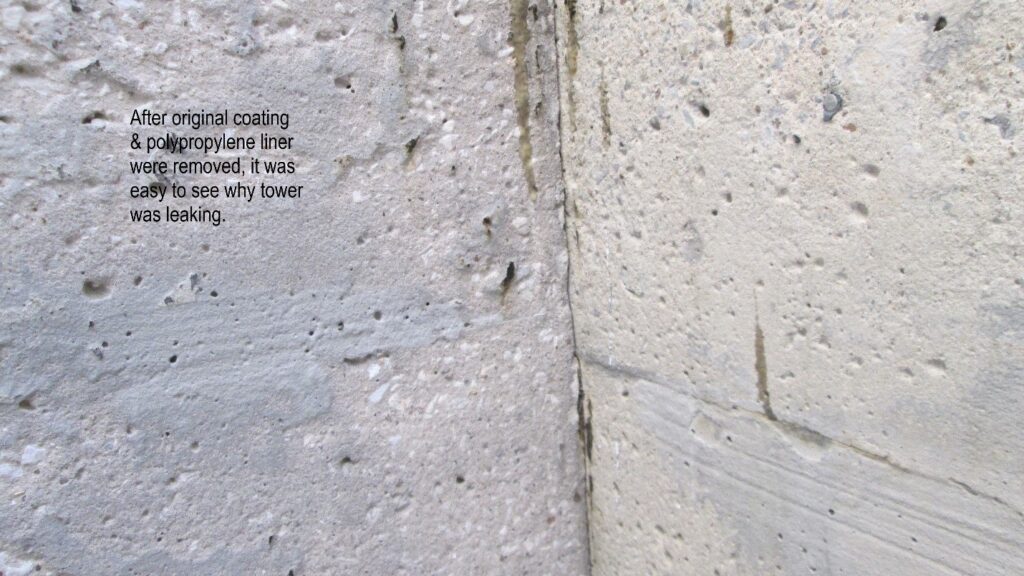

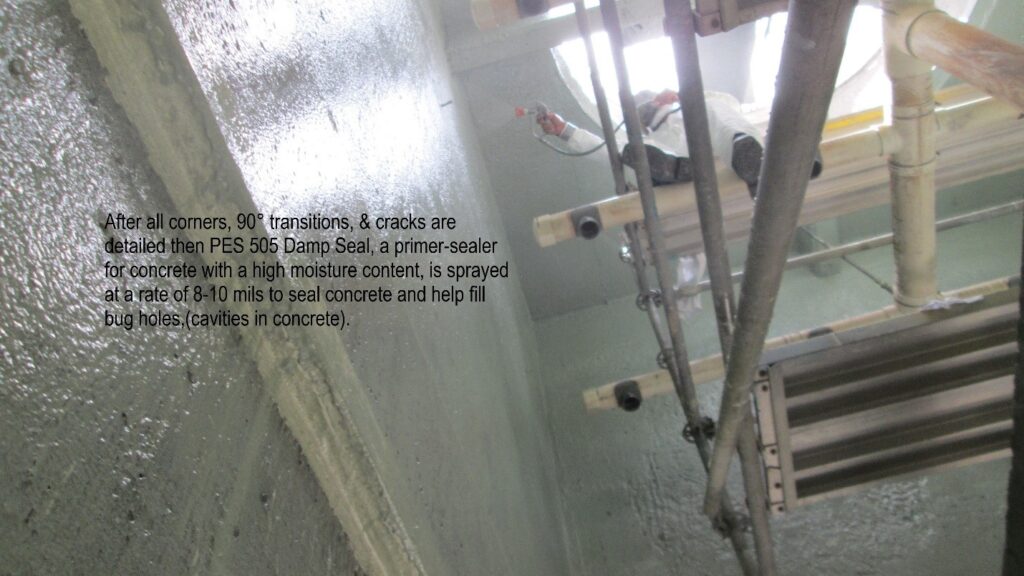

After the fill cut in the photo above, note the seam under fill that can now be mechanically prepared with a right-angle grinder and sealed with PES 577 joint filler, and then our coating system is applied.

In the picture above, instead of removing all the fill media, this tower had a PES Lone Star Fill Cut. The fill was protected using thin plywood, and then the basin was grit blasted to NACE standard #2 near white metal (SSPC-SP10) with a 3–4 mil angular anchor pattern. PES then coated with two coats of PES 507 DWPU at twenty mils per coat. PES 507 DWPU is a two-component solvent free polyurethane coating that has been designed to be applied to steel and primed concrete surfaces. The coating has UK WRAS BS 6920 approval for contact and immersion conditions with drinking water, and excellent chemical resistance to chlorination agents such as 15% Sodium Hypochlorite, Chlorine and Chlorine Dioxide.

We apply this product with a brush, roller, or spray. When cured, it gives flexible, long-term chemical and corrosion protection to steel and concrete surfaces.

Another great coating for both metal and concrete cooling towers is the PES 501 Series, which has a range of two-component solvent-free epoxy coatings that have been designed to be applied to steel and primed concrete surfaces. The products are applied by brush, roller, or spray and offer excellent chemical resistance to a wide range of aqueous industrial chemicals. The coatings are suitable for all areas of chemical process plants and equipment and are tolerant of less-than-ideal surface preparation.

PES can offer many more solutions to everyday Cooling Tower problems, such as motor and gear box change-outs, fan pitch, drive shaft replacement, drift eliminators, and fill media change-outs.

If you have any questions, please give us a call at 979-779-8700 or email pes1@pes-solutions.com.