PES Solutions uses HOLZ metal bellows. HOLZ metallic expansion joints solve the most demanding challenges facing the industry in air, gas and media problems within complex piping and ducting systems. Metallic or metal expansion joints are often used when an extreme temperature range is between -420°F to +1800°F. Additionally, metal joints can handle pressure up to 1,000 psi.

While the metal strength is an advantage in certain application, a metallic expansion joint has the disadvantage of reduced spring rates coupled with thrust forces. Additional supplies such as anchors, gaskets, or covers/liners are required in most applications where metallic expansion joints are used.

It is important to evaluate the pros and cons of metallic vs. rubber expansion joints in your particular application.

Metallic Expansion Joint Applications

Our Metal Expansion Joints supplied by HOLZ have a wide range of applications and each expansion joint is designed based on its unique environmental and installation conditions; pressure, temperature, movements, space and/or corrosion, etc.

Metallic expansion joints are primarily used for:

- Fossil fuel power generation

- Pressure vessel manufacturing

- Desalination power plant

- Petrochemical industry

- Oil refineries industry

- Chemical and pharmaceutical industry

- Marine applications

- District heating

- Pulp and paper

- Iron and steel mills

- Cryogenics industry

- Automotive industry

- Instrumentation industry

- Waste water treatment

Types of Metal Expansion Joints Supplied by HOLZ

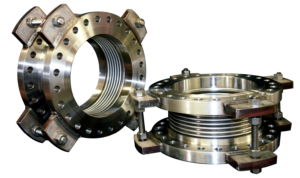

HOLZ Single Bellow Joint

The Single Bellow Joint is the most fundamental form of a metallic expansion joint which consists of a single bellows (flex element) typically welded to flanged and/or pipe ends. It is designed based on its unique environmental and installation conditions including pressure, temperature, movements, space and/or corrosion, etc. It is designed in compliance with EJMA standards. This expansion joint compensates for movement that occurs within the pipe section in which it is installed.

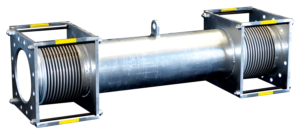

HOLZ Universal Expansion Joint

Consisting of two bellows connected by a common center spool with flanged and/or pipe ends, the Universal Expansion Joint is designed to allow greater lateral movement than a single bellow metallic expansion joint. It is manufactured for unique environmental and installation conditions; pressure, temperature, movements, space and/or corrosion, etc.

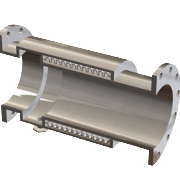

HOLZ External Pressurized Expansion Joint

The External Pressurized Expansion Joint is designed based on its unique environmental and installation conditions including pressure, temperature, movements, space and/or corrosion, etc. The line pressure acts on the external surfaces of bellows by means of an external pressure chamber. This expansion joint allows for a greater number of convolutions to be used for large axial movements without losing bellows stability.

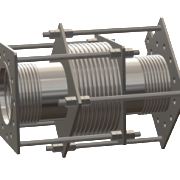

Pressure Balanced (Elbow and Inline) Expansion Joint

The Pressure Balanced Expansion Joint is designed to address pressure thrust while absorbing axial/lateral movements accomplished by the addition of equalizing bellows tied to the flow bellows in such a way as to cancel opposing forces induced by pressure.

Rectangular/Square — Folded Corner (Camera Bellows Style) and Mitered

The Folded Corner and Mitered are low-pressure bellows designed for ducting and fan applications.

Types of Connections

Weld End (Pipe or Rolled Plate)

The weld end is typically constructed from ASTM A53 Gr. B or A106 Gr. B pipe up to 24-inch in diameter and pipe or rolled plate for larger sizes. Stainless and alloys are also available.

Flanged (Forged or Plate and Angle)

Standard ANSI flanges are selected to match the specified design pressure and are available up to 24-inch in diameter. Larger flanges are fabricated from plate steel. All flanges can be made of stainless and other alloys available in plate form.

Van Stone (Floating Flange)

This special arrangement allows for the rotation of the flanges about the centerline to accommodate the misalignment of bolt patterns flange to flange. This design also prevents the flange from contacting wet and corrosive processes, thus allowing lesser grades of steel for the flanges — substantially reducing final cost.

Accessories

Control/Limiting Devices

Control/Limiting devices are designed to restrict or distribute movements during typical operation.

Tie Rods

These are used to restrain full pressure thrust during typical operation while permitting only lateral movement.

Hinges

Hinges restrict movement to angular only.

Liner

Also known as flow shields or sleeves, this accessory is designed to minimize flow induced erosion and/or vibration. Liners can be very simple or somewhat complex depending on the application.

Covers (Shrouds)

Covers protect the external surface of the bellows from mechanical damage, debris, nearby weld spatter, etc. and can be permanently attached or removable.

If you need your expansion joint replaced or repaired, PES has you covered! Contact us today with the link below for more information!

Nice post! Metal bellows are fabricated to tight tolerances in a variety of materials for use in clean rooms and ultrahigh-vacuum applications.

Nice post defining the true information about metal bellow. Really, the metal bellow is used for a variety of applications.